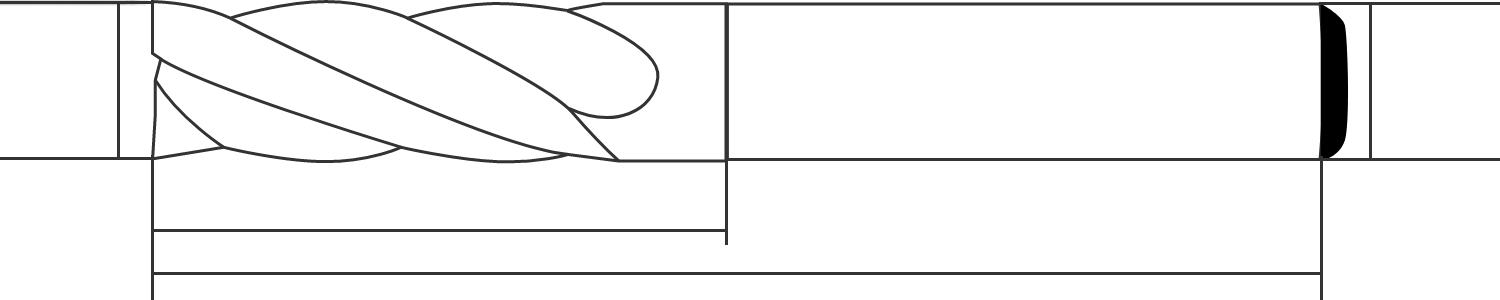

Alüminyum HRC55 için Kaba Freze

Kare Frezeler

Alüminyum için Kaba Freze HRC55, işleme verimliliğini artırmak, takım ömrünü uzatmak ve kaliteyi sağlamak için tasarlanmış, alüminyum işlemeye yönelik özel bir frezedir. Bu freze, alüminyum alaşımlarının işleme gereksinimlerini karşılamak için özel takım geometrileri ve malzemeler içerir.

Ürün Özellikleri:

Yüksek ısı iletkenliğine sahip malzemenin benimsenmesi, takım sıcaklığını etkili bir şekilde azaltır ve yüksek sıcaklığın neden olduğu aşınma ve deformasyonu önler, özellikle yüksek hızlı, büyük kesme derinliğine sahip alüminyum işleme için uygundur.

Yüzey kaplama veya özel işlem, kesici yüzeyinin yapışmasını önler, yapışma olgusunu azaltır ve takım ömrünü uzatır.

Yüksek hızlı kesim için uygundur:

Yapı, titreşimi ve gürültüyü azaltacak şekilde tasarlanmıştır ve yüksek hızlı kesimde istikrarlı bir performans sergileyerek işleme verimliliğini artırır.

Özel olarak tasarlanmış kesme geometrisi yüksek hassasiyet ve yüzey kalitesi sağlar, kesme kuvvetlerini azaltır ve kesme stabilitesini artırır.