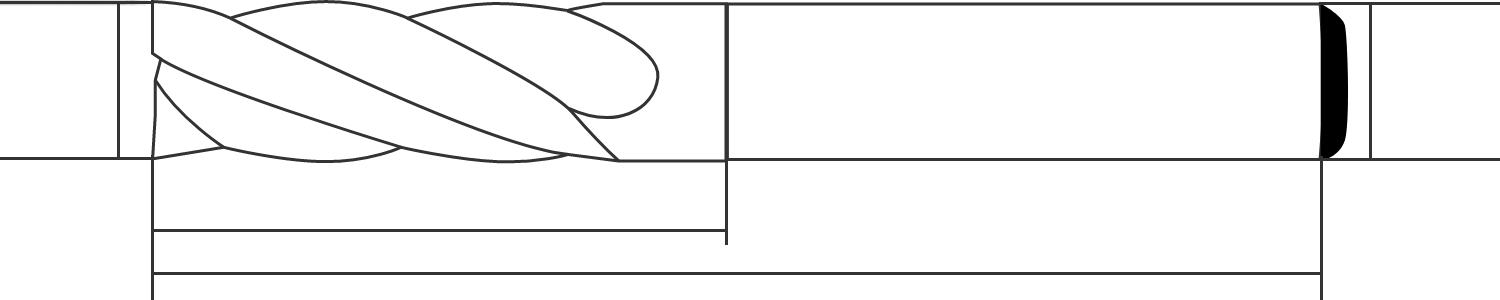

D

D2

L

L2

Birim

(mm)

D

D≤12

D>12

T

0

0

-0.015

-0.02

Çapd

D

Kesme

Uzunluk L

Şaft

D2

Toplam UzunlukKesme

L2

Sipariş Kodu

CPD550-4F-04120450

CPD550-4F-04120450

CPD550-4F-04120450

CPD550-4F-04120450

CPD550-4F-04120450

CPD550-4F-04120450

CPD550-4F-04120450

CPD550-4F-04120450

CPD550-4F-04120450

CPD550-4F-04120450

CPD550-4F-04120450

Iso

İş Parçası Malzemesi

Kesme derinliği (mm)

VC

m/dak

P

<45HRC

Karbon Çelik Alaşımlı Çelik50HRC

Alaşımlı Çelik

Ap≤1D

Ap≤0,5d

80

60

Rote Hızı (Min-1)

Besleme Hızı (Mm/Min)

K

<32HRC

Gry Dökme Demir, Nodüler Dökme Demir35-45HRC

Yüksek Alaşımlı Dökme Demir

Ap≤1D

Ap≤0,8

55

55

Rote Hızı (Min-1)

Besleme Hızı (Mm/Min)

P

4250

760

2390

700

2550

660

2120

640

1590

640

1270

710

3190

380

2390

380

1910

380

1590

380

1190

330

960

310

K

2920

370

2190

370

1750

360

1460

350

1100

310

880

280

2920

350

2390

380

1750

350

1460

320

1133

290

880

280

Yukarıdaki tablo, yan işleme için standart kesme verileridir, f oluk kesme için, VC 50%-70%'ye ulaşmalı ve besleme tabloya göre 40%-60%'ye ulaşmalıdır.

Düz bir yüzey oluşturmak için çelik bir plakanın işlenmesi

Düz bir yüzey oluşturmak için çelik bir plakanın işlenmesi

Düz bir yüzey oluşturmak için çelik bir plakanın işlenmesi

Düz bir yüzey oluşturmak için çelik bir plakanın işlenmesi

Bir 55 kaba çelik parmak frezenin kullanıldığı uygulama örneği

Düz bir yüzey oluşturmak için çelik bir plakanın işlenmesi

Omuz oluşturmak için çelik bir parçanın işlenmesi

Çelik bir yuvanın işlenmesi

Çelik bir parçanın kenarlarına pah kırma

Soruşturma

Çeşitli Sorgular

E-posta Dergisi Kaydı