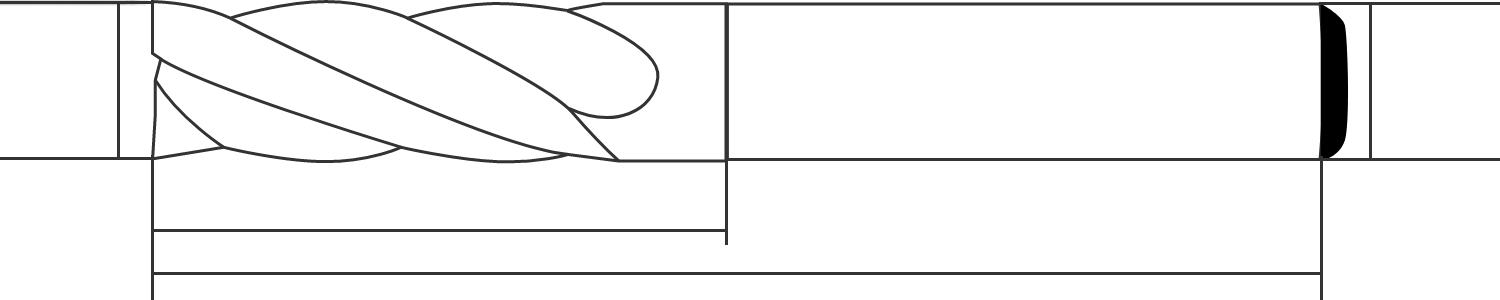

Karbür Matkap ile 5D Soğutma Sıvısı

Kare Frezeler

5D dahili soğutucu matkap, öncelikle havacılık ve uzay bileşenleri ve otomotiv motor parçaları gibi karmaşık yapıların işlenmesinde kullanılan yüksek performanslı bir kesici takımdır. Benzersiz tasarımı, yüksek sıcaklık, yüksek hız ve yüksek hassasiyetli kesme ortamlarında olağanüstü iyi performans göstermesini sağlar. Geleneksel soğutma yöntemleriyle karşılaştırıldığında, dahili soğutma sıvısı teknolojisi kesme verimliliğini etkili bir şekilde artırır, takım ömrünü uzatır ve işleme süreci sırasında termal deformasyonu azaltır.

Ürün Özellikleri:

Dahili Soğutucu Teknolojisinin Avantajı:

5D dahili soğutma sıvılı matkap, kesme bölgesi içinde soğutma sıvısının akmasını sağlayan dahili soğutma sıvısı teknolojisini kullanır. Bu, takımın ve iş parçasının sıcaklıklarını etkili bir şekilde düşürerek ısının malzemeler üzerindeki etkisini azaltır. Bu sadece kesme verimliliğini artırmakla kalmaz, aynı zamanda yüksek sıcaklıkların neden olduğu takım aşınmasını da önler.

Yüksek Hassasiyetli İşleme:

Benzersiz tasarımı ve dahili soğutma sıvısı teknolojisi sayesinde 5D dahili soğutma sıvısı matkabı, yüksek hızlı ve yüksek hassasiyetli işlemede olağanüstü iyi performans gösterir. Modern üretimin katı hassasiyet gereksinimlerini karşılayarak karmaşık yapıların hassas bir şekilde işlenmesini sağlayabilir.

Güçlü Malzeme Uyumluluğu:

Bu kesici takım, yüksek sıcaklık alaşımları ve titanyum alaşımları dahil olmak üzere çeşitli zorlu malzemeler için uygundur. Takım malzemeleri ve kaplama teknolojileri özenle seçilmiştir ve zorlu çalışma ortamlarında istikrarlı performans sağlar.

Artan Üretim Verimliliği:

5D içten soğutmalı matkabın verimli kesme ve soğutma sistemi, işleme sürecini dengeler. Duruş süresini azaltarak ve kesme hızlarını artırarak üretim verimliliğini etkili bir şekilde geliştirir ve üretim maliyetlerini düşürür.