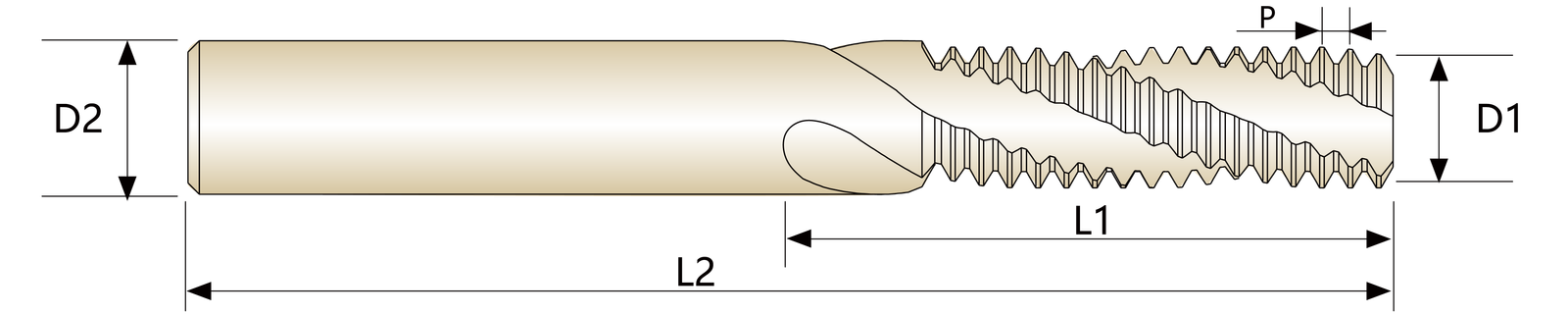

Fresa de rosca de três formas

Fresas de topo quadradas

A Fresa de Roscar Três Formas é uma ferramenta especificamente concebida para a maquinação de materiais metálicos de elevada dureza. A sua filosofia de conceção visa proporcionar uma fresagem de roscas eficiente e precisa, adequada para o processamento de aços com uma dureza de 55 graus. Esta fresa utiliza processos e materiais avançados para garantir um desempenho excecional em ambientes de maquinagem complexos.

Caraterísticas do produto:

Material de elevada dureza Aplicabilidade:

A fresa de rosca de três formas foi especificamente concebida para lidar com materiais metálicos de elevada dureza, garantindo estabilidade e longevidade durante o processo de maquinagem.

Fresagem eficiente de roscas:

Com um design de três dentes, o processo de fresagem torna-se mais eficiente e preciso. Este design contribui para aumentar a eficiência do processamento, reduzir o tempo de produção e garantir a qualidade da fresagem de roscas.

Processos e materiais avançados:

A utilização de processos de fabrico avançados e de materiais de alta qualidade garante a resistência ao desgaste e a durabilidade da fresa. Isto ajuda a reduzir a frequência das substituições de ferramentas, melhorando a eficiência global da produção.

Adequação a ambientes de maquinagem complexos:

A estrutura de design permite um desempenho excecional ao lidar com processos complexos e tarefas de maquinação desafiantes. É adequado para aplicações que requerem roscas de alta precisão e qualidade, satisfazendo os requisitos rigorosos de desempenho da ferramenta.