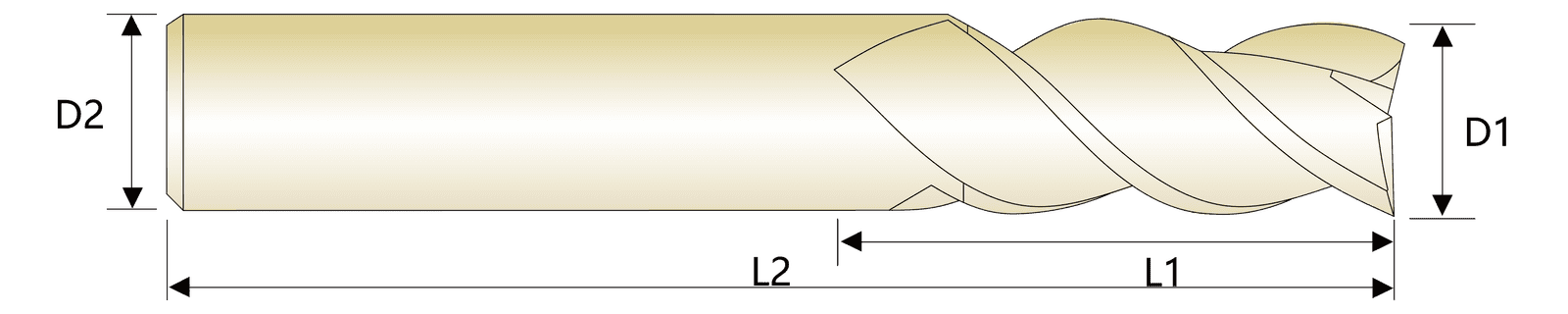

Fresa de topo quadrada HRC68

Fresas de topo quadradas

A fresa de topo quadrada ST-KK Serie Variable Helix é uma ferramenta especial para cortar, tornear e fresar alumínio. Devido à natureza especial do alumínio, as ferramentas convencionais deparam-se com um desgaste rápido da ferramenta, resultados de corte fracos, etc. A fresa de topo quadrada ST-KK Serie Variable Helix foi optimizada para resolver estes problemas e melhorar a eficiência da maquinação e a qualidade do produto.

Caraterísticas do produto:

Design de vanguarda optimizado:

A fresa de topo quadrada ST-KK Serie Variable Helix apresenta um design de aresta de corte cuidadosamente optimizado que reduz a resistência ao corte, reduz o desgaste da ferramenta, prolonga a vida útil da ferramenta e melhora a eficiência do corte.

Seleção de material resistente ao desgaste:

Seleção de carboneto cimentado de material altamente resistente ao desgaste, para aumentar a resistência ao desgaste da ferramenta, para garantir que a ferramenta mantém a estabilidade de corte durante muito tempo, para melhorar a precisão da maquinação.

Design da extremidade quadrada:

O design da extremidade quadrada garante uma excelente evacuação das aparas, evitando a sua obstrução e melhorando a eficiência da maquinagem.

Capaz de efetuar várias operações de maquinagem, incluindo fresagem de ranhuras, fresagem lateral e fresagem de contornos, com ampla aplicabilidade.

Controlo de corte de precisão:

Permite uma maquinação mais fina e melhora a qualidade da superfície dos produtos de alumínio para aplicações com elevadas exigências de precisão e aparência.