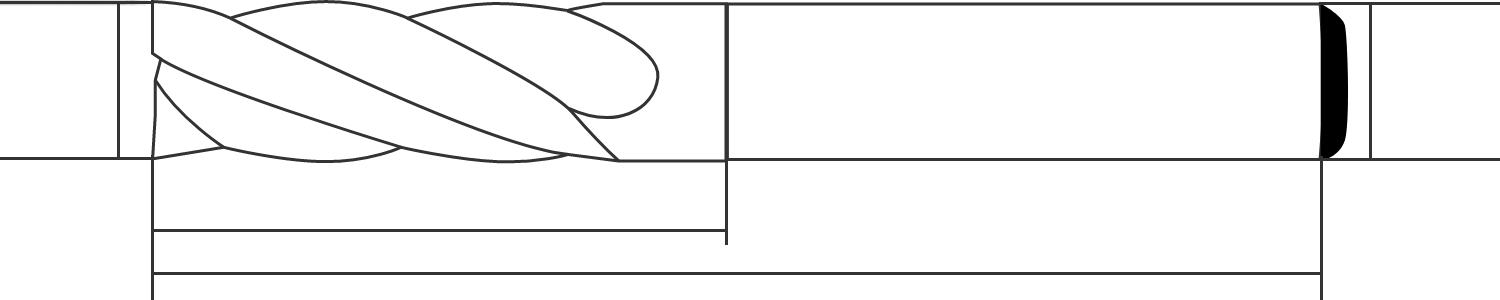

Fresa de topo de raio de canto de hélice variável da série ST-U

Fresas de topo quadradas

A fresa de topo de raio de canto de hélice variável da série ST-U é uma gama de ferramentas concebidas profissionalmente para melhorar a eficiência e a precisão da maquinagem. A sua construção única e os materiais de alta qualidade tornam-nas ideais para utilização no fabrico moderno. Quer se trate de metalurgia, moldagem de plásticos ou processamento de outros materiais, a Fresa de Topo de Canto de Hélice Variável da Série ST-H demonstra um desempenho e fiabilidade excepcionais.

Caraterísticas do produto:

Material da faca de qualidade e duradouro:

A fresa de topo de raio de canto de hélice variável ST-U Serie é fabricada com materiais de ferramenta de corte de alta qualidade, como carboneto ou HSS, o que lhe confere uma excelente resistência ao desgaste e durabilidade. Isto assegura que as facas permanecem afiadas durante longos períodos de tempo, reduzindo a frequência das mudanças de ferramentas e aumentando a produtividade.

Geometria única da ferramenta:

As ferramentas desta série foram concebidas com uma forma especial que as torna adequadas para maquinar uma vasta gama de superfícies curvas e contornos. Esta geometria não só proporciona uma gama mais ampla de capacidades de maquinagem, como também ajuda a reduzir a vibração e a aumentar a estabilidade de corte, melhorando assim a qualidade da superfície maquinada.

Design de corte eficiente:

A fresa de topo de raio de canto de hélice variável da série ST-U apresenta um design de ferramenta avançado que torna o processo de corte mais eficiente. Ao otimizar a geometria da aresta de corte, o ângulo de flanco e a estrutura da aresta, é capaz de aumentar a velocidade de corte enquanto reduz a resistência ao corte, poupando assim tempo de maquinação e reduzindo custos.

Flexibilidade de aplicação versátil:

Esta série de facas é amplamente utilizada para cortar e maquinar uma variedade de materiais, incluindo metais, plásticos, compósitos e muito mais. Quer seja no fabrico automóvel, aeroespacial ou na maquinação de moldes e matrizes, as fresas de topo de raio de canto de hélice variável da série ST-U são capazes de realizar diferentes tarefas, demonstrando uma versatilidade e flexibilidade extraordinárias.