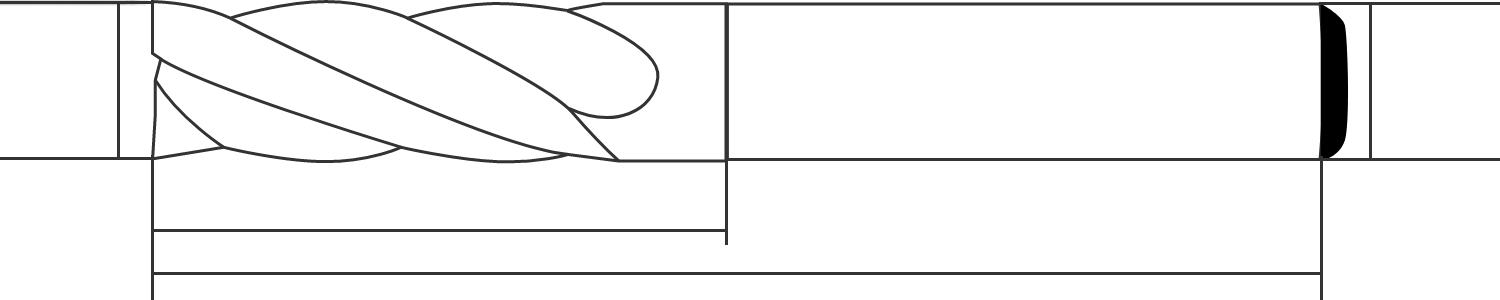

D

D2

L

L2

Unidade

(mm)

D

D≤12

D>12

T

0

0

-0.015

-0.02

Diâmetrod

D

Corte

Comprimento L

Haste

D2

Comprimento totalCorte

L2

Código de encomenda

ST-H-4F-01030450

ST-H-4F-015050450

ST-H-4F-02060450

ST-H-4F-025080450

ST-H-4F-03090450

ST-H-4F-04120450

ST-H-4F-05130650

ST-H-4F-06180650

ST-H-4F-08200860

ST-H-4F-10301075

ST-H-4F-12361275

ST-H-4F-144014100

ST-H-4F-164516100

ST-H-4F-185018100

ST-H-4F-205020100

ST-H-4F-03120475

ST-H-4F-04160475

ST-H-4F-05200675

ST-H-4F-06250675

ST-H-4F-08320875

ST-H-4F-031204100

ST-H-4F-041604100

ST-H-4F-062506100

ST-H-4F-083208100

ST-H-4F-104010100

ST-H-4F-125012100

ST-H-4F-064506150

ST-H-4F-085008150

ST-H-4F-105510150

ST-H-4F-126012150

ST-H-4F-166516150

ST-H-4F-208020150

Iso

Material da peça de trabalho

Profundidade de corte (mm)

VC

m/min

P

<45HRC

Aço-carbono Aço-liga

50HRC

Aço de liga leve

Ap≤1D

Ap≤0.5d

80

60

Velocidade do Rote (Min-1)

Velocidade de avanço (Mm/Min)

K

<32HRC

Ferro fundido cinzento, ferro fundido nodular

35-45HRC

Ferro fundido de alta liga

Ap≤1D

Ap≤0,8

55

55

Velocidade do Rote (Min-1)

Velocidade de avanço (Mm/Min)

Diâmetro da ferramenta (mm)

P

4250

760

2390

700

2550

660

2120

640

1590

640

1270

710

3190

380

2390

380

1910

380

1590

380

1190

330

960

310

K

2920

370

2190

370

1750

360

1460

350

1100

310

880

280

2920

350

2390

380

1750

350

1460

320

1133

290

880

280

A tabela acima é o padrão de dados de corte para usinagem de laminação lateral, f para corte de ranhuras, o VC deve atingir 50%-70% e o alimentado deve atingir 40%-60% com base na tabela.

Maquinação de uma chapa de aço para criar uma superfície plana

Maquinação de uma chapa de aço para criar uma superfície plana

Maquinação de uma chapa de aço para criar uma superfície plana

Maquinação de uma chapa de aço para criar uma superfície plana

Exemplo de uma aplicação que utiliza a fresa de topo quadrada de alta precisão da série ST-H

Desbaste da cavidade do molde

Fresagem de elementos complexos e arestas vivas

Obtenção de um acabamento de superfície liso

Manter uma qualidade consistente em toda a produção

Inquérito

Vários Inquéritos

Registo da revista por e-mail