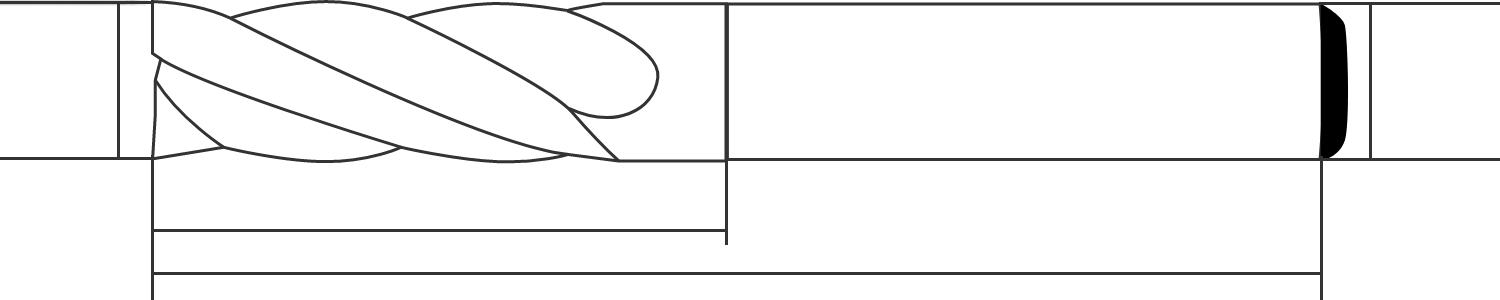

Fresa de topo de raio de canto de alta precisão da série ST-H

Fresas de topo quadradas

A fresa de topo de raio de canto de alta precisão da série ST-H é uma série de ferramentas de corte profissional conhecida pelo seu elevado desempenho e versatilidade. Não só são excelentes em termos de resistência ao desgaste, como também garantem a estabilidade do corte através de processos de fabrico avançados, proporcionando aos utilizadores soluções de maquinagem eficientes e fiáveis.

Caraterísticas do produto:

Processos de fabrico avançados:

A fresa de topo de raio de canto de alta precisão da série ST-H utiliza processos de fabrico de última geração para garantir a precisão e a estabilidade da ferramenta. Isto permite que as ferramentas se destaquem numa variedade de ambientes de maquinação complexos.

Excelente resistência ao desgaste:

Devido à utilização de materiais de alta qualidade, a fresa de topo de raio de canto de alta precisão da série ST-H tem uma excelente resistência ao desgaste, o que prolonga a vida útil da ferramenta e reduz os custos de substituição da ferramenta para os utilizadores.

Esta série de facas foi concebida para ser flexível e versátil para uma variedade de necessidades de maquinagem diferentes. A Fresa de Topo de Raio de Canto de Alta Precisão da Série ST-H proporciona resultados de corte eficientes e precisos tanto para maquinação em bruto como para maquinação fina.

Desempenho de corte estável:

A fresa de topo de raio de canto de alta precisão da série ST-H tem um bom desempenho durante o processo de corte, mantendo uma boa estabilidade de corte, reduzindo a vibração e o desgaste da ferramenta e garantindo a qualidade da superfície e a precisão das peças maquinadas.