Fresa de rosca multiformes para alumínio

Moinhos de rosca

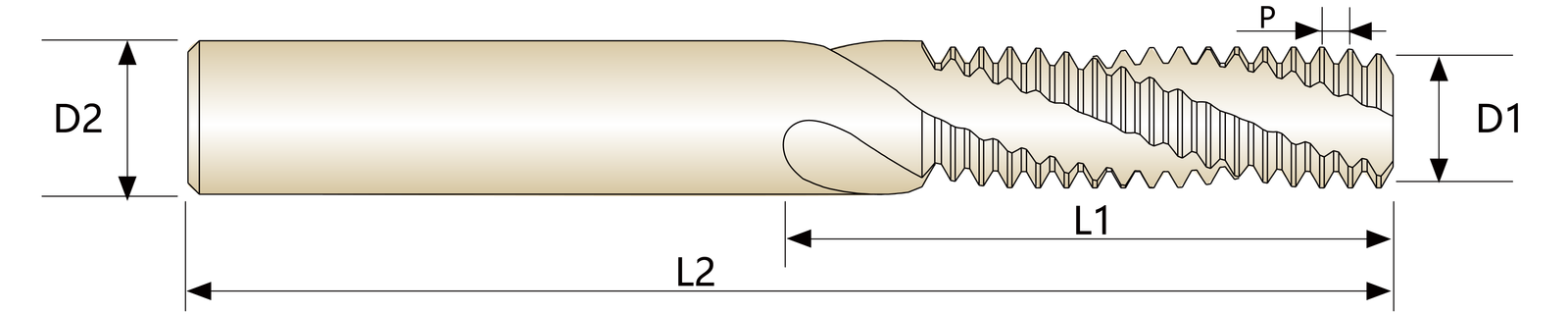

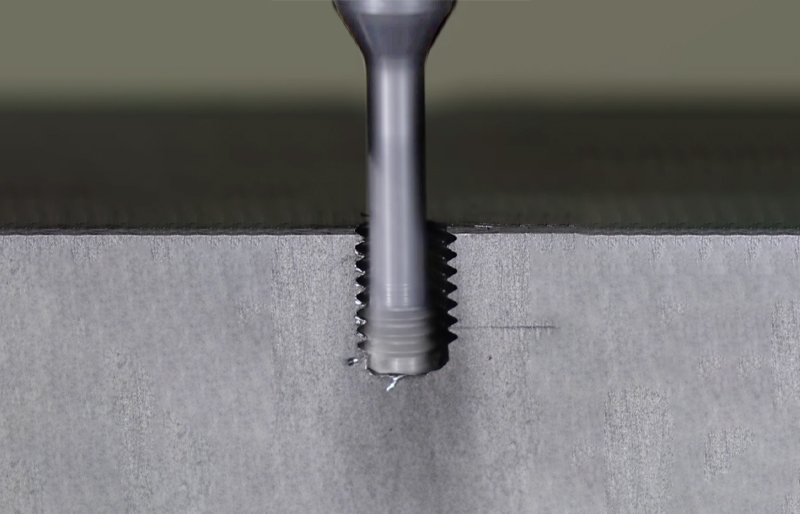

A fresa de rosca multiformes é uma ferramenta de corte eficiente e precisa, utilizada principalmente para a fresagem de aço. A sua conceção é inspirada por um profundo conhecimento das caraterísticas especiais da maquinagem do aço, com o objetivo de melhorar a eficiência da maquinagem, reduzir os custos e garantir a qualidade das peças maquinadas. O design de rosca única da fresa, combinado com a sua estrutura roscada, permite-lhe lidar melhor com a dureza e a resistência ao desgaste do aço durante o corte a alta velocidade.

Caraterísticas do produto:

A fresa de rosca multiformes adopta um design de rosca única, que reduz eficazmente a resistência do contacto entre a ferramenta e a peça de trabalho e melhora a eficiência de corte. Este design pode cortar o aço mais facilmente durante o corte a alta velocidade, reduzindo o tempo de processamento e melhorando a eficiência da produção.

Excelente resistência ao desgaste:

A estrutura da rosca confere à fresa uma boa estabilidade de corte. Ao processar aço, a fresa de rosca multiformes pode dispersar as forças de corte de forma mais uniforme, reduzir a vibração e o batimento da ferramenta, garantir a estabilidade do processo de processamento e ajudar a obter superfícies de processamento de maior precisão.

A estrutura da rosca confere à fresa uma boa estabilidade de corte. Ao processar aço, as fresas de rosca simples podem dispersar as forças de corte de forma mais uniforme, reduzir a vibração e o batimento da ferramenta, garantir a estabilidade do processo de processamento e ajudar a obter superfícies de processamento de maior precisão.

O design multi-dentes permite que a fresa corte a superfície do aço com maior precisão, reduzindo os erros de corte. Isto é particularmente importante para alguns sectores industriais que exigem peças de elevada precisão. Ao utilizar esta fresa, pode garantir peças com elevada precisão e excelente qualidade de superfície.