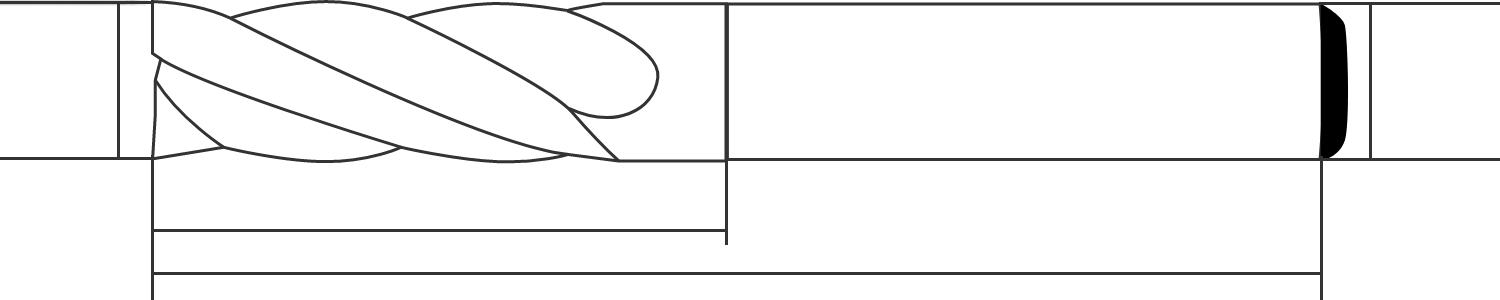

Fresa de topo de ponta esférica HRC55

Fresas de topo quadradas

A fresa de topo de ponta esférica HRC55 é uma ferramenta concebida para a maquinação de superfícies esféricas ou curvas e é amplamente utilizada na indústria metalúrgica. O seu design e caraterísticas únicas tornam-na numa ferramenta ideal para obter uma elevada precisão e qualidade de superfície.

Caraterísticas do produto:

A fresa de topo de ponta esférica HRC55 foi concebida para permitir um corte altamente preciso em superfícies curvas, assegurando que as peças de trabalho têm o tamanho e a forma exactos. Isto é fundamental para o fabrico de componentes que requerem um elevado grau de precisão, como nas indústrias aeroespacial e automóvel.

Devido às caraterísticas de corte da fresa de topo de ponta esférica HRC55, é capaz de proporcionar uma excelente qualidade de superfície durante a maquinagem. Isto é fundamental para aplicações que requerem suavidade da superfície da peça e controlo da rugosidade da superfície, como o fabrico de moldes e matrizes e a produção de instrumentos de precisão.

Vasta gama de aplicações:

A fresa de topo de ponta esférica HRC55 pode ser utilizada para processar uma vasta gama de materiais, incluindo aço, alumínio e aço inoxidável. A sua versatilidade torna-as úteis em diferentes campos industriais, satisfazendo as necessidades de diferentes materiais e processos.

Aumento da produtividade:

A fresa de topo de ponta esférica HRC55 pode maquinar peças complexas num período de tempo mais curto, graças ao seu design, que lhe permite efetuar cortes multidireccionais em superfícies curvas. Isto melhora a produtividade e reduz os tempos de ciclo de maquinação, o que é especialmente importante em cenários de produção em massa.