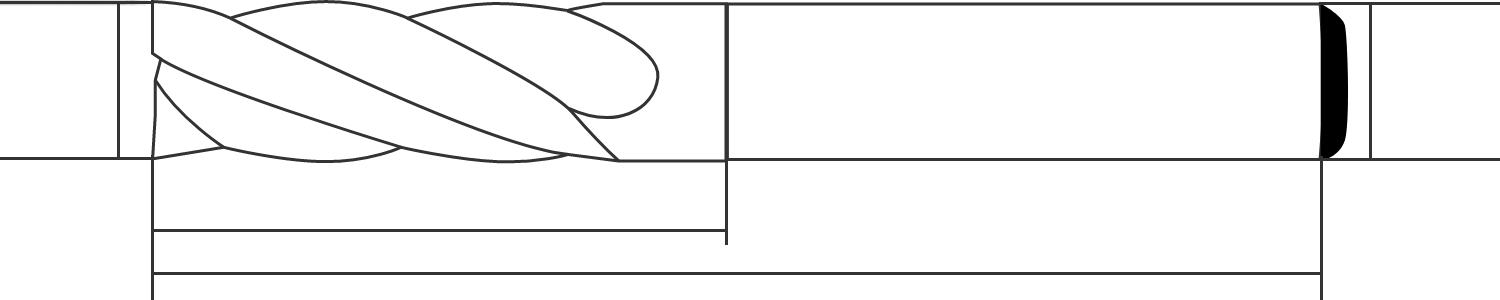

D

D2

L

L2

Unit

(mm)

D

D≤12

D>12

T

0

0

-0.015

-0.02

Diameterd

D

Cutting

Length L

Shank

D2

Overall LengthCutting

L2

Ordering Code

ST-H-4F-01030450

ST-H-4F-015050450

ST-H-4F-02060450

ST-H-4F-025080450

ST-H-4F-03090450

ST-H-4F-04120450

ST-H-4F-05130650

ST-H-4F-06180650

ST-H-4F-08200860

ST-H-4F-10301075

ST-H-4F-12361275

ST-H-4F-144014100

ST-H-4F-164516100

ST-H-4F-185018100

ST-H-4F-205020100

ST-H-4F-03120475

ST-H-4F-04160475

ST-H-4F-05200675

ST-H-4F-06250675

ST-H-4F-08320875

ST-H-4F-031204100

ST-H-4F-041604100

ST-H-4F-062506100

ST-H-4F-083208100

ST-H-4F-104010100

ST-H-4F-125012100

ST-H-4F-064506150

ST-H-4F-085008150

ST-H-4F-105510150

ST-H-4F-126012150

ST-H-4F-166516150

ST-H-4F-208020150

Iso

Workpiece Material

Depth of cut (mm)

VC

m/min

P

<45HRC

Carbon Steel Alloy Steel

50HRC

Alloy Steel

Ap≤1D

Ap≤0.5d

80

60

Rote Speed (Min-1)

Feed Velocity (Mm/Min)

K

<32HRC

Gry Cast Iron, Nodular Cast Iroron

35-45HRC

High Alloy Cast Iron

Ap≤1D

Ap≤0.8

55

55

Rote Speed (Min-1)

Feed Velocity (Mm/Min)

P

4250

760

2390

700

2550

660

2120

640

1590

640

1270

710

3190

380

2390

380

1910

380

1590

380

1190

330

960

310

K

2920

370

2190

370

1750

360

1460

350

1100

310

880

280

2920

350

2390

380

1750

350

1460

320

1133

290

880

280

Above table is the standard cutting data for side mlling maching, f for groove cutting, the VC should reach 50%-70% and the fed should reach 40%-60% based on the table.

Machining a steel plate to create a flat surface

Machining a steel plate to create a flat surface

Machining a steel plate to create a flat surface

Machining a steel plate to create a flat surface

Example of an application using ST-H Serie High Precision Square End Mill

Milling intricate features and sharp edges

Achieving a smooth surface finish

Maintaining consistent quality throughout production

Inquiry

Various Inquiry

E-mail Magazine Registration