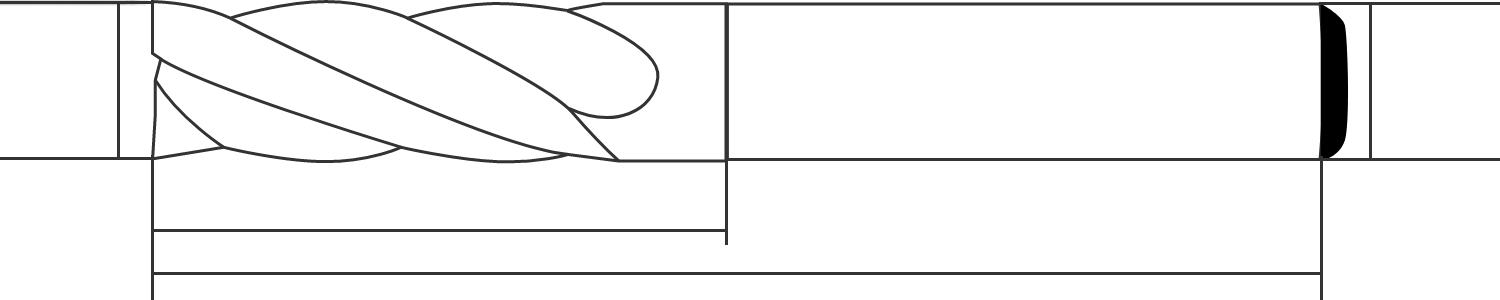

Square End Mill HRC55

Square End Mills

Corner Radius End Mill HRC55 is a cutter used for machining metals and other hard materials with good cutting performance. This milling cutter is typically used in a wide range of processes such as milling and contouring to provide high precision machining of workpieces.

Product Features:

Superior Cutting Performance:

The Corner Radius End Mill HRC55 provides smooth and efficient cutting during machining. This design lowers cutting resistance, reduces cutting heat generation and effectively extends tool life.

The Corner Radius End Mill HRC55 is designed to excel in contouring. The rounded profile of the cutter head allows for a smooth cutting path that accurately replicates the shape required by the design, thus meeting the need for high-precision machining.

Stable Cutting Entry and Exit:

The Corner Radius End Mill HRC55 provides smoother entry and exit from the workpiece during the cutting process, reducing vibration and shock, which contributes to improved machining efficiency and quality. This feature is especially important for machining complex surfaces.

Suitable for a wide range of materials:

The design of the Corner Radius End Mill HRC55 makes it suitable for machining a wide range of hard materials, including metals, plastics and composites. This versatility makes the Corner Radius End Mill HRC55 one of the most commonly used tools in industrial production for a wide range of applications.