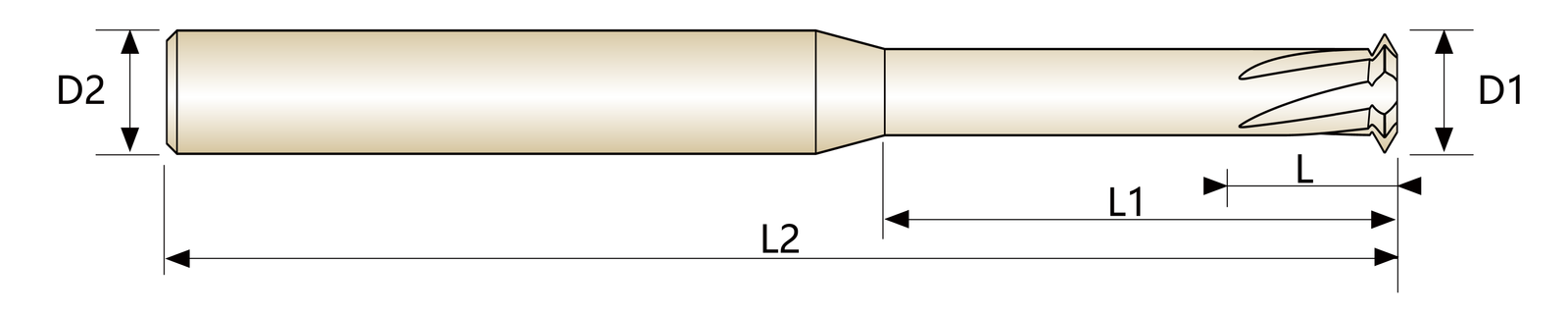

Single Form Thread Mill For Aluminum

Thread Mills

Single Form Thread Mill is an efficient and precise cutting tool mainly used for milling of steel. Its design is inspired by a deep understanding of the special characteristics of steel machining, aiming to improve machining efficiency, reduce costs and ensure the quality of machined parts. The milling cutter’s single-threaded design, combined with its threaded structure, allows it to better cope with the hardness and wear resistance of steel during high-speed cutting.

Product Features:

The Single Form Thread Mill adopts a single-thread design, which effectively reduces the resistance of the contact between the tool and the workpiece and improves cutting efficiency. This design can cut into steel more easily during high-speed cutting, reducing processing time and improving production efficiency.

Excellent Wear Resistance:

The thread structure gives the milling cutter good cutting stability. When processing steel, Single Form Thread Mill can disperse cutting forces more evenly, reduce vibration and tool beat, ensure the stability of the processing process, and help obtain higher-precision processing surfaces.

The thread structure gives the milling cutter good cutting stability. When processing steel, single-thread thread milling cutters can disperse cutting forces more evenly, reduce vibration and tool beat, ensure the stability of the processing process, and help obtain higher-precision processing surfaces.

The single tooth design allows the milling cutter to cut the steel surface more accurately, reducing cutting errors. This is particularly important for some industrial fields that require high precision of parts. By using this milling cutter, you can ensure parts with high precision and excellent surface quality.