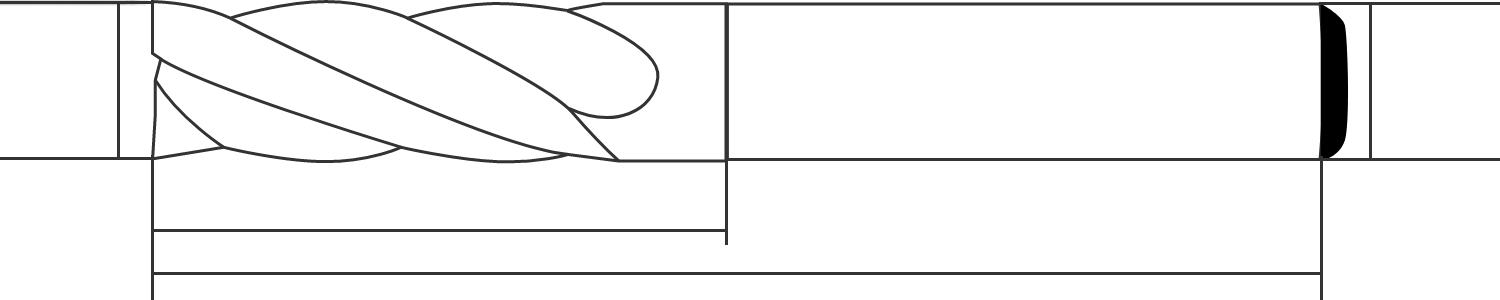

Long Neck Square End Mill HRC55

Square End Mills

Introducing our Long Neck Square End Mill HRC55, designed for precision machining with exceptional durability. With a high Rockwell hardness of HRC55, this tool delivers consistent performance in cutting a wide range of materials. Its extended neck design provides access to hard-to-reach areas, making it the perfect choice for intricate and high-precision machining tasks. Elevate your machining capabilities with our Long Neck Square End Mill HRC55, engineered for excellence in every cut.

Product Features:

Crafted with precision, this end mill boasts a high Rockwell hardness rating of HRC55, ensuring durability and longevity in demanding machining applications.

Versatility is key – this tool is designed to handle a wide range of materials, from metals to plastics, delivering consistent and precise cuts across various workpieces.

The extended neck allows for access to tight and hard-to-reach areas, making it ideal for intricate and high-precision machining tasks.

Experience superior performance and reliability with this end mill, engineered to meet the highest machining standards and exceed your expectations.