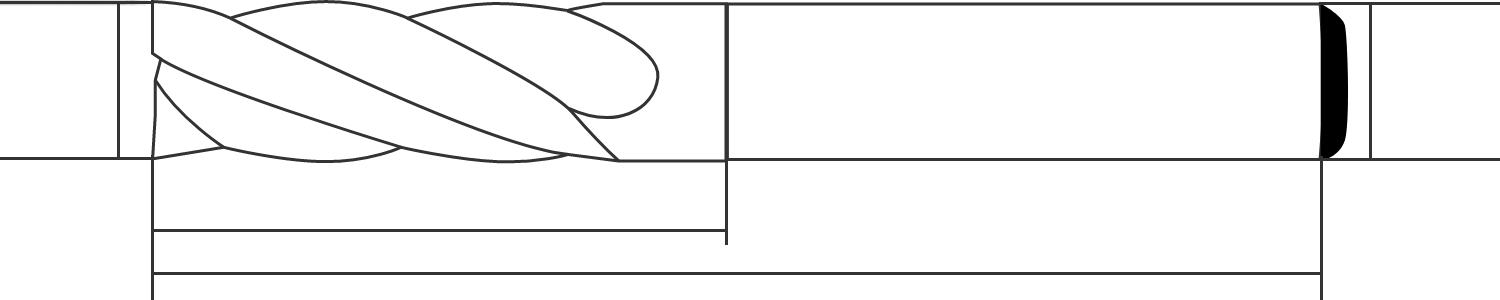

Dovetail End Mill HRC55

Square End Mills

The Dovetail End Mill HRC55 is a cutting-edge tool tailored for machining high-hardness materials. Employing advanced materials and manufacturing processes, it ensures remarkable stability and wear resistance during cutting. The tool’s design aims to enhance machining efficiency, reduce processing costs, and ensure the precision and surface quality of the final parts.

Product Features:

The Dovetail End Mill HRC55 utilizes materials with a high hardness of HRC55, enabling it to easily tackle workpieces with elevated hardness. This hardness not only enhances the tool’s wear resistance but also prolongs its service life.

The tool features an accurate Dovetail shape, contributing to improved cutting stability and machining precision. The Dovetail End Mill HRC55 ensures the production of fine surface quality during processing, reducing the need for subsequent machining operations.

Efficient Cutting Design:

The tool’s efficient design allows for the swift removal of cutting materials, significantly boosting machining efficiency. This makes the Dovetail End Mill HRC55 an ideal choice for processing high-hardness workpieces, especially in applications requiring high precision.

Thanks to its HRC55 hardness and flexible design, the Dovetail End Mill HRC55 is suitable for processing a variety of materials, including steel, stainless steel, alloys, and more. This broad applicability ensures outstanding performance in different industries and fields.