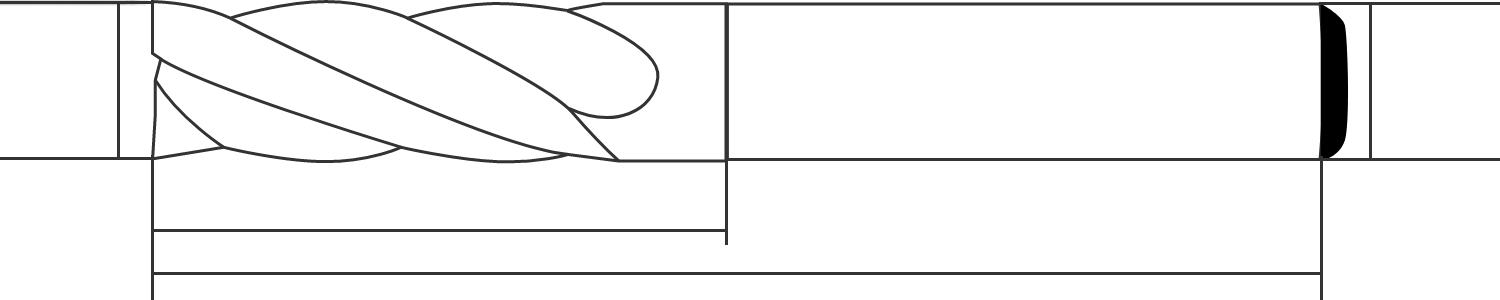

Chamfer Tool HRC55

Square End Mills

The Chamfer Tool HRC55 is a meticulously designed cutting tool suitable for various metal machining applications. With a hardness of HRC55, it ensures exceptional performance under high loads and harsh cutting conditions. This tool excels in chamfering processes, delivering superior cutting effects and wear resistance, thereby providing high-quality surface finishes for workpieces.

Product Features:

The material hardness of the Chamfer Tool HRC55 reaches HRC55, signifying its ability to maintain stable performance under high loads and high-speed cutting conditions. This makes it an ideal choice for processing hard metals and other materials with challenging cutting requirements.

Outstanding Cutting Performance:

The tool employs advanced cutting geometry and blade design, ensuring superior cutting effects during chamfering. This not only enhances production efficiency but also maintains high precision and smoothness on the workpiece surface.

The Chamfer Tool HRC55 is manufactured using wear-resistant materials, allowing it to retain excellent edge sharpness and wear resistance during prolonged cutting operations. This contributes to extending the tool’s lifespan and reducing production costs.

The tool is suitable for a variety of metal machining applications, including steel, aluminum alloys, stainless steel, and more. Its versatile design makes it an ideal choice for handling different materials and complex workpieces, enhancing processing flexibility and efficiency.