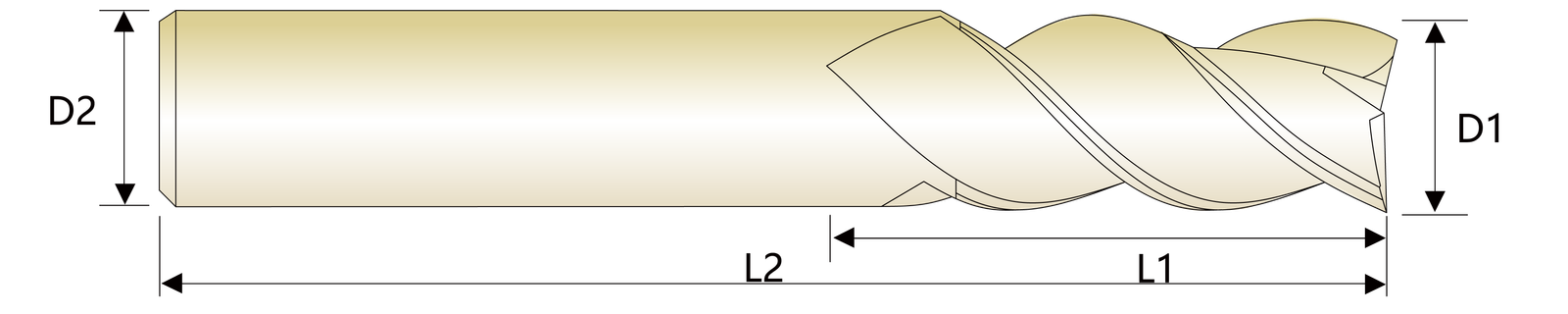

Carbide 4Flutes Square End Mill HRC70

Square End Mills

Carbide 4Flutes Square End Mill is a milling cutter specifically designed for

Square machining, delivering outstanding performance and versatility. With high hardness, strong

wear resistance, and the ability to achieve high-precision machining across various materials, it

stands as an ideal choice to enhance machining efficiency and workpiece quality.

Product Features:

Manufactured from high-hardness materials with a typically hardness

level above 70HRC, the Carbide 4Flutes Square End Mill HRC70 easily handles workpieces of varying hardness, ensuring

minimal deformation and wear over prolonged use, thus extending its operational lifespan.

Excellent Wear Resistance:

This milling cutter exhibits exceptional wear resistance, maintaining

sharp cutting edges during high-speed machining, reducing wear rates, and extending its overall

lifespan. This feature is particularly crucial in environments requiring frequent and extensive

machining.

Precision in design and blade grinding processes ensures that the Carbide 4Flutes

Square End Mill HRC70 achieves high-precision surface quality and geometric shapes during machining,

meeting the demands for precision in workpiece specifications.

Suitable for a variety of materials, including but not limited to steel,

aluminum, copper, etc. This versatility makes the Carbide 4Flutes Square End Mill HRC65 an ideal choice for diverse

industrial applications, catering to the machining needs of different workpieces.