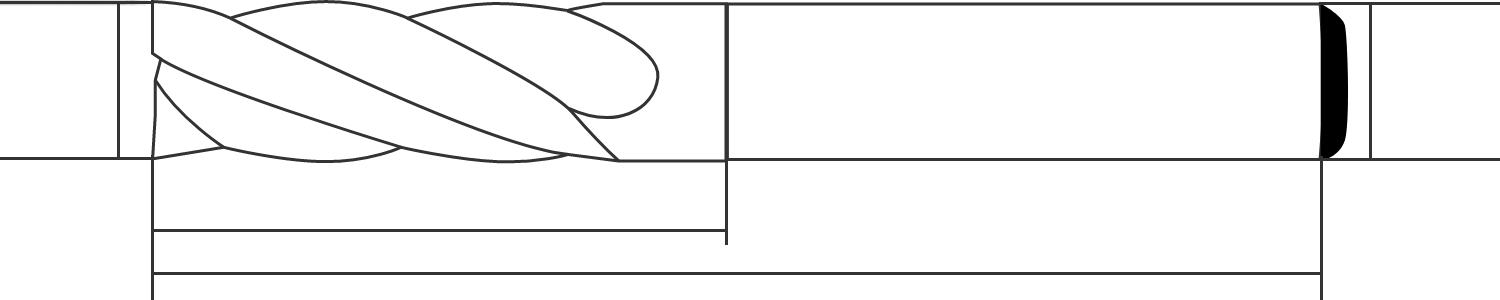

Ball Nose End Mill HRC55

Square End Mills

The Ball Nose End Mill HRC55 is a tool designed for the machining of spherical or curved surfaces and is widely used in the metalworking industry. Its unique design and features make it an ideal tool for achieving high precision and surface quality.

Product Features:

The Ball Nose End Mill HRC55 has been designed to allow highly precise cutting on curved surfaces, ensuring that workpieces are of exact size and shape. This is critical for the manufacture of components that require a high degree of precision, such as in the aerospace and automotive industries.

Due to the cutting characteristics of Ball Nose End Mill HRC55, it is able to provide excellent surface quality during machining. This is critical for applications that require part surface smoothness and surface roughness control, such as mould and die making and precision instrument production.

Wide range of applications:

The Ball Nose End Mill HRC55 can be used to process a wide range of materials including steel, aluminium and stainless steel. Their versatility makes them useful in different industrial fields, meeting the needs of different materials and processes.

The Ball Nose End Mill HRC55 can machine complex parts in a shorter period of time, thanks to its design, which allows it to make multi-directional cuts on curved surfaces. This improves productivity and reduces machining cycle times, which is especially important in mass production scenarios.