Aluminum Inner Radius End Mill HRC55

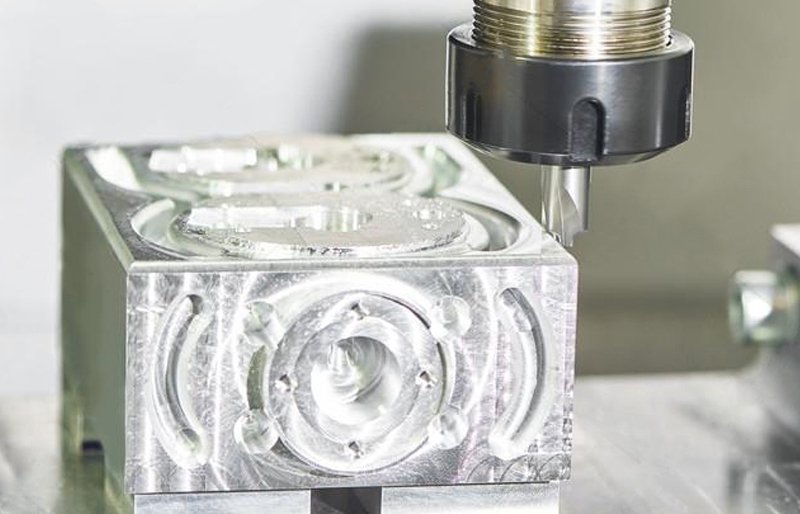

Inner Radius End Mills

The Corner Rounding End Mill HRC55 is renowned for its outstanding performance and versatile applications. Designed to provide efficient metal machining solutions, it has become an indispensable tool in modern manufacturing.

Product Features:

Excellent Hardness (HRC55):

Manufactured with materials and heat treatment processes ensuring a hardness of 55 HRC, this milling cutter effortlessly tackles the cutting demands of high-hardness metals, maintaining a prolonged tool life..

The precise design of the tool geometry allows the Corner Rounding End Mill HRC55 to achieve accurate contour machining, ensuring superior accuracy and surface quality in the final product. This makes it excel in tasks requiring precision.

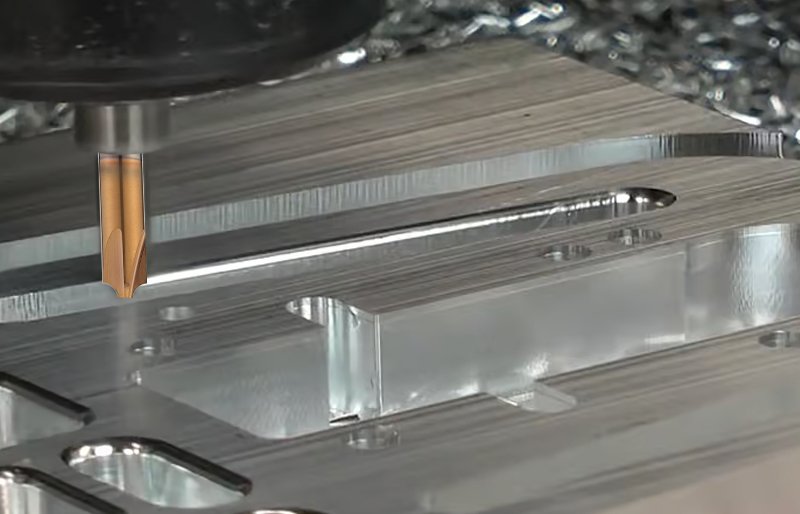

Efficient Cutting Performance:

Advanced tool coating technology reduces friction and enhances cutting speed, increasing production efficiency. Whether for rough or finish machining, it reliably and swiftly completes tasks.

The milling cutter is suitable for various metal materials, including steel, aluminum, copper, etc., making it an ideal choice when facing diverse machining needs. Its versatility and applicability find widespread use across different industries and sectors.