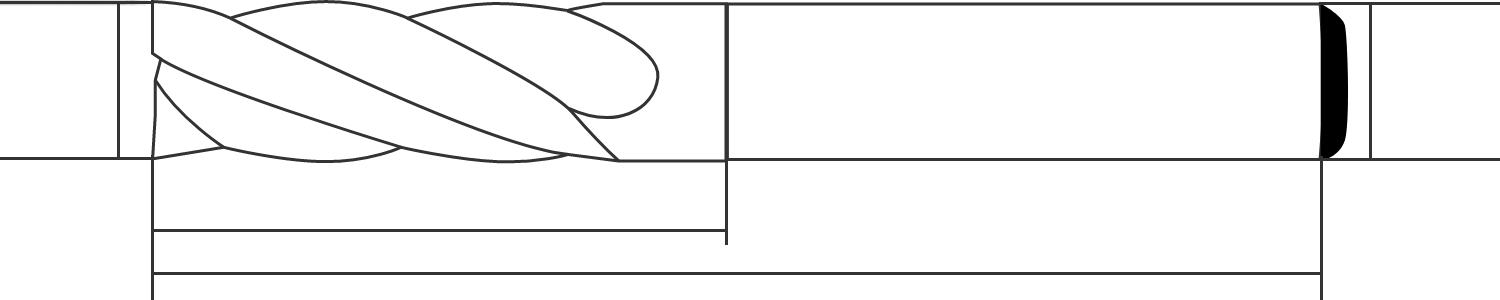

3D Coolant Through Carbide Drill

Square End Mills

The 3D internal coolant drill is an advanced cutting tool that employs an integrated cooling system, providing a reliable solution for efficient and precise machining. Its design aims to reduce tool temperature during the cutting process through internal cooling channels, enhancing cutting efficiency and making it suitable for processing various complex materials, including high-temperature alloys and hard materials.

Product Features:

Integrated Cooling System:

The 3D internal coolant drill adopts advanced internal cooling technology, rapidly reducing the temperature in the cutting zone through internal cooling channels. This effectively minimizes heat accumulation during the cutting process, extending the tool’s lifespan.

Suitability for Multi-material Machining:

Due to its flexible design, the 3D internal coolant drill is suitable for processing a variety of complex materials, including high-temperature alloys and hard materials. This makes it an ideal choice for handling different workpieces, enhancing processing versatility.

The 3D internal coolant drill possesses excellent high-precision machining capabilities, enabling precise cutting of complex structures and small holes. This elevates product quality and machining accuracy in the manufacturing industry.

Increased Production Efficiency:

By reducing tool temperature and minimizing friction and thermal deformation during the cutting process, the 3D internal coolant drill effectively enhances cutting efficiency. This contributes to shorter processing cycles, improved production efficiency, and reduced manufacturing costs.