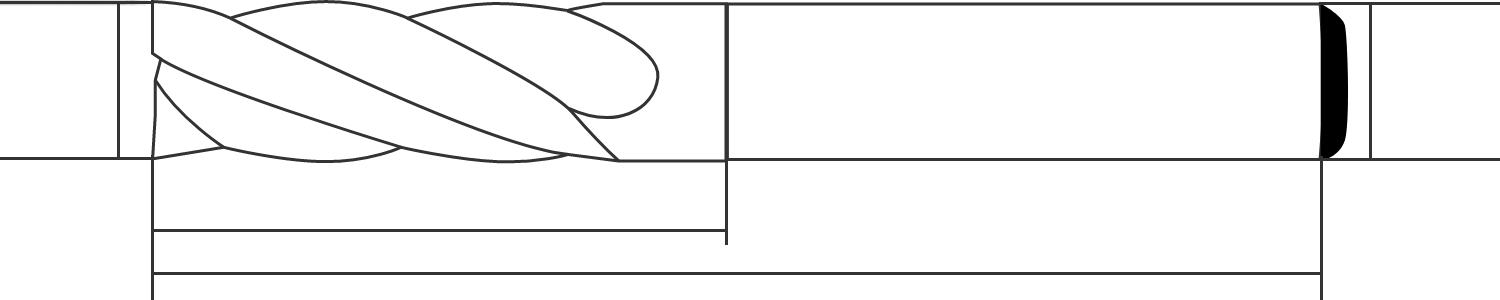

Fresa de mango cuadrada de hélice variable serie ST-U

Fresas cuadradas

La fresa de mango cuadrada de hélice variable de la serie ST-U es una herramienta versátil ideal para una amplia gama de aplicaciones de desbaste y acabado del acero. Su geometría de hélice variable proporciona una acción de corte suave y reduce las vibraciones, lo que se traduce en un acabado superficial de alta calidad.

Características del producto:

Excelente acabado superficial:

No se conforme con bordes ásperos. Este diseño inteligente minimiza la vibración, dejando un acabado suave que a menudo elimina la necesidad de pasadas de acabado adicionales, ahorrándole tiempo y dinero.

Carburo de tungsteno de primera calidad:

Este material sólido como una roca resiste incluso a los aceros más duros, garantizando una larga vida útil de la herramienta y un rendimiento constante, corte tras corte.

Eliminación más rápida del material:

Haga más en menos tiempo. El corte eficiente y la evacuación superior de virutas se traducen en tiempos de mecanizado más rápidos, lo que aumenta su producción y mantiene sus proyectos en marcha.

Reducción de los costes de acabado:

Deje que la herramienta haga el trabajo de acabado. El excelente acabado superficial a menudo elimina la necesidad de un acabado posterior, ahorrándole tiempo, recursos y dinero.