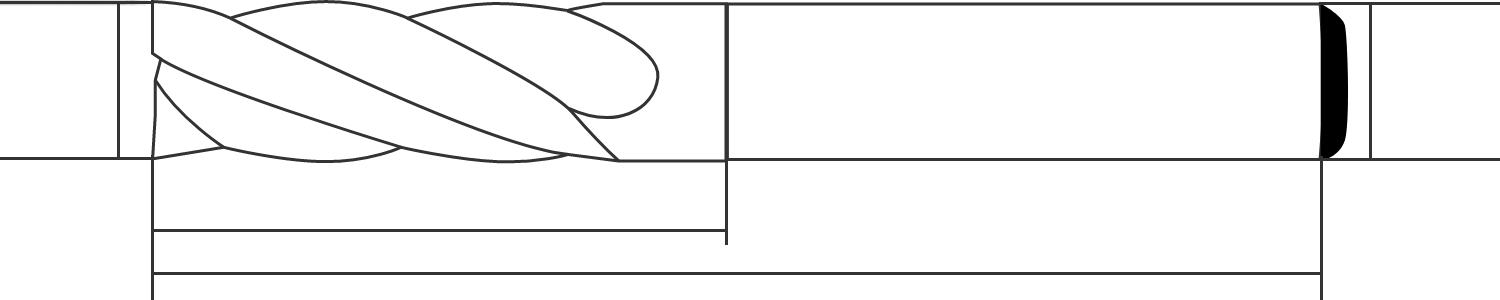

Herramienta de biselado HRC55

Fresas cuadradas

La herramienta para chaflanes HRC55 es una herramienta de corte meticulosamente diseñada para diversas aplicaciones de mecanizado de metales. Con una dureza de HRC55, garantiza un rendimiento excepcional bajo cargas elevadas y condiciones de corte duras. Esta herramienta destaca en los procesos de chaflanado, ofreciendo unos efectos de corte y una resistencia al desgaste superiores, proporcionando así unos acabados superficiales de alta calidad para las piezas de trabajo.

Características del producto:

La dureza del material de la herramienta de chaflanado HRC55 alcanza el HRC55, lo que significa su capacidad para mantener un rendimiento estable bajo cargas elevadas y condiciones de corte a alta velocidad. Esto la convierte en la elección ideal para procesar metales duros y otros materiales con requisitos de corte exigentes.

Rendimiento de corte excepcional:

La herramienta emplea una geometría de corte y un diseño de cuchilla avanzados que garantizan unos efectos de corte superiores durante el biselado. Esto no sólo mejora la eficiencia de la producción, sino que también mantiene una alta precisión y suavidad en la superficie de la pieza de trabajo.

Gran resistencia al desgaste:

La herramienta para chaflanes HRC55 se fabrica con materiales resistentes al desgaste, lo que le permite conservar un excelente filo y resistencia al desgaste durante operaciones de corte prolongadas. Esto contribuye a prolongar la vida útil de la herramienta y a reducir los costes de producción.

La herramienta es adecuada para diversas aplicaciones de mecanizado de metales, como acero, aleaciones de aluminio y acero inoxidable, entre otros. Su diseño versátil la convierte en la opción ideal para manipular diferentes materiales y piezas de trabajo complejas, mejorando la flexibilidad y la eficacia del procesamiento.