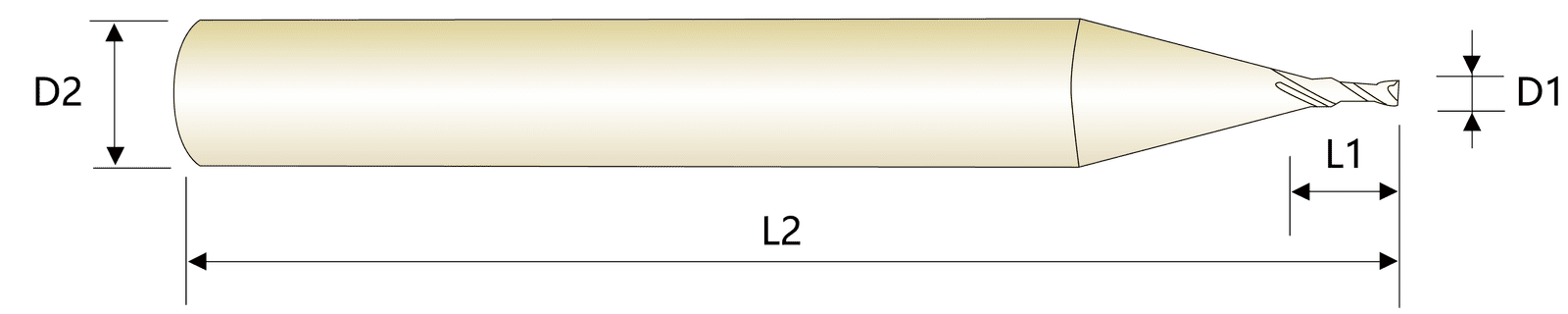

Mikro-Durchmesser-Vierkantfräser HRC60

Vierkant-Schaftfräser

The Square End Mill HRC45 is a milling cutter specifically designed for

Square machining, delivering outstanding performance and versatility. With high hardness, strong

wear resistance, and the ability to achieve high-precision machining across various materials, it

stands as an ideal choice to enhance machining efficiency and workpiece quality.

Produktmerkmale:

Manufactured from high-hardness materials with a typically hardness

level above 60HRC, the Square End Mill HRC45 easily handles workpieces of varying hardness, ensuring

minimal deformation and wear over prolonged use, thus extending its operational lifespan.

Hervorragende Abriebfestigkeit:

Dieser Fräser weist eine außergewöhnliche Verschleißfestigkeit auf und behält

scharfe Schneiden bei der Hochgeschwindigkeitsbearbeitung, reduziert die Verschleißrate und verlängert seine

Lebensdauer. Diese Eigenschaft ist besonders wichtig in Umgebungen, die häufige und umfangreiche

Bearbeitung erfordern.

Feinmechanische Bearbeitung:

Precision in design and blade grinding processes ensures that the Square

End Mill HRC60 achieves high-precision surface quality and geometric shapes during machining,

meeting the demands for precision in workpiece specifications.

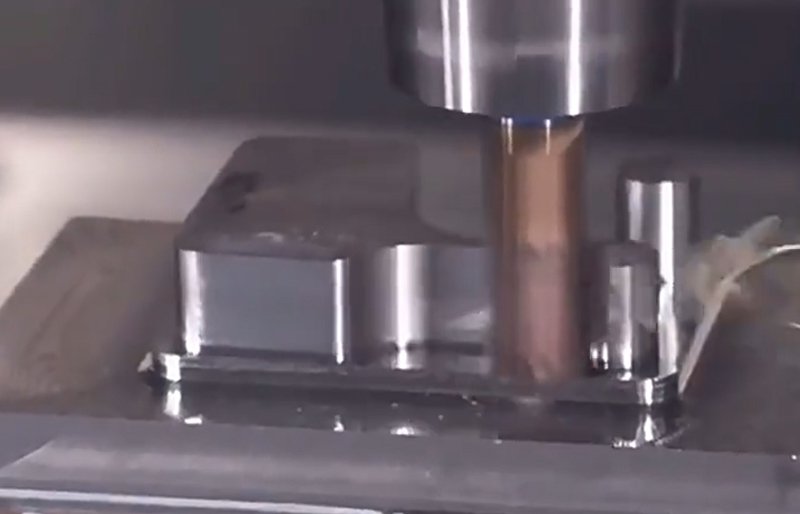

Geeignet für eine Vielzahl von Materialien, einschließlich, aber nicht beschränkt auf Stahl,

Aluminium, Kupfer, etc. Diese Vielseitigkeit macht den Vierkantfräser HRC45 zu einer idealen Wahl für verschiedene

industrielle Anwendungen, die den Bearbeitungsanforderungen unterschiedlicher Werkstücke gerecht werden.