HANDERK

– Manufacturer Of Precision Tools

Changzhou HANDERK Precision Tools Co., Ltd. is located in Xixiashu, a famous tool town in China, with elegant environment and convenient transportation.

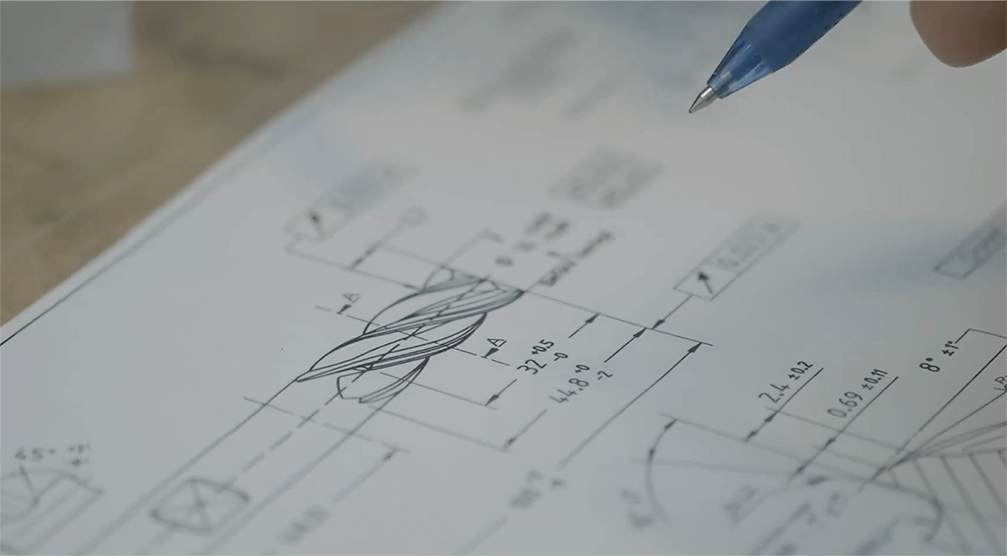

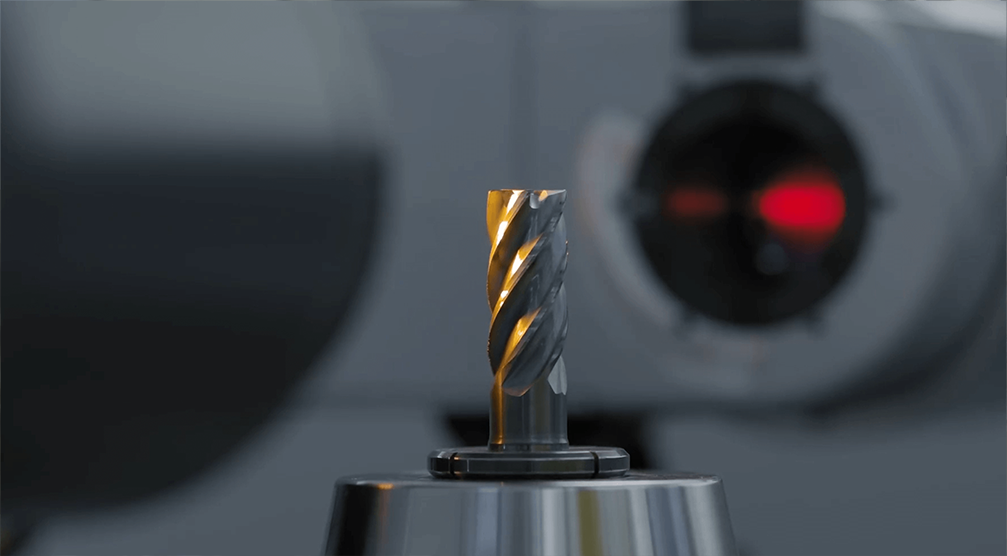

Founded in 2000, the company specializes in the production of CNC cutting tools including Carbide End Mills, Carbide Drills, Carbide Inserts, etc. We have relatively complete product development, manufacturing, and sales capabilities, and has taken the lead in passing the ISO9001:2018 international quality management system certification.

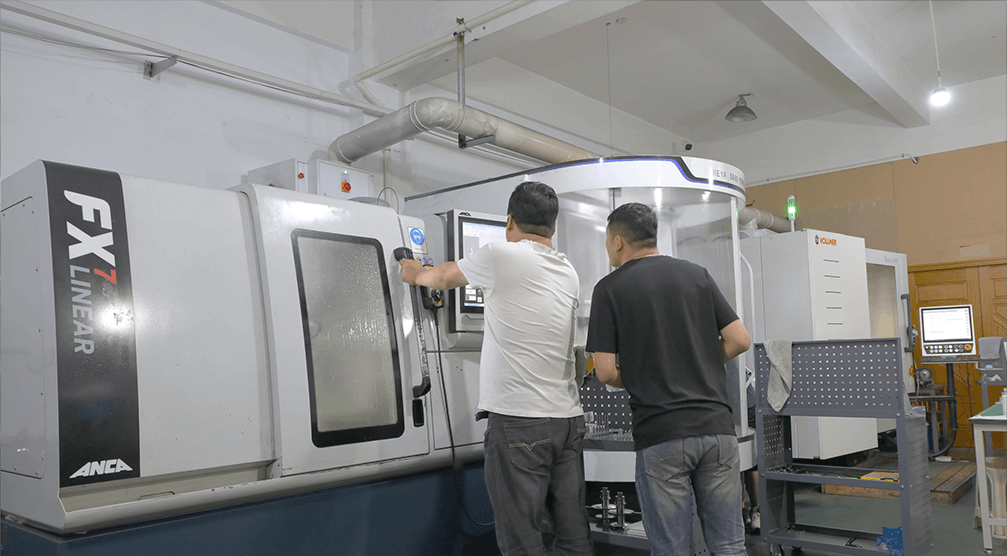

Up to now, HANDERK has a total asset of more than 200 million RMB, three branch factories with a total area of 6,000 square meters and over 120 employees. 160 sets of domestic and imported equipment, including SAGE, WALTER, and ANCA, manufacture different products respectively, with thousands of stocks for each product specification.